ROMI GL Series – New Generation

Turning Centers

Presentation

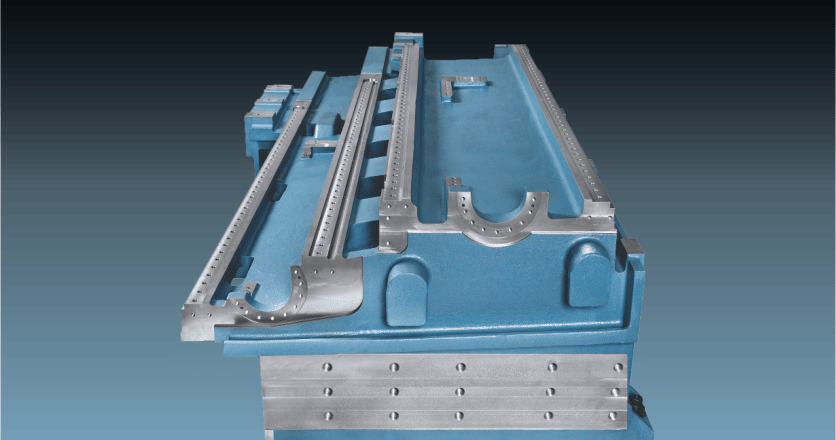

Designed to operate in environments of medium and high production, the ROMI GL Series has high power and torque. Its robust structure is ideal for machining at full power. It offers high rigidity even during severe machining operations. Thermal and geometric stability, grants accuracy, high performance and productivity.

The quality of the manufacturing processes grants reliability and operational efficiency of ROMI machines. Projected in 3D CAD system, the entire structure of the ROMI GL SERIES is dimensioned by Finite Element Analysis software (FEA), resulting in adequate structures for each machine size.

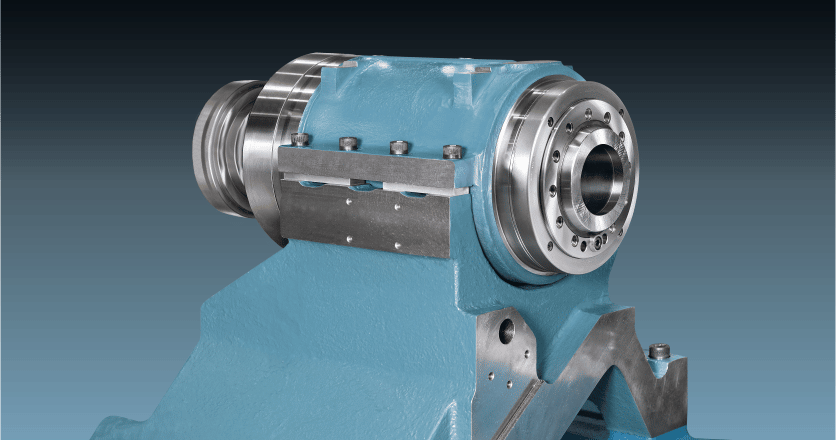

Offers huge power and torque; has a cooling system which brings great thermal and geometric stability to the assembly. High precision spindle is designed to withstand high machining forces and high speeds with continuous variation.

Main technical features

| ROMI GL 250 | ROMI GL 300 | ROMI GL 350 | ROMI GL 450 | ||

|---|---|---|---|---|---|

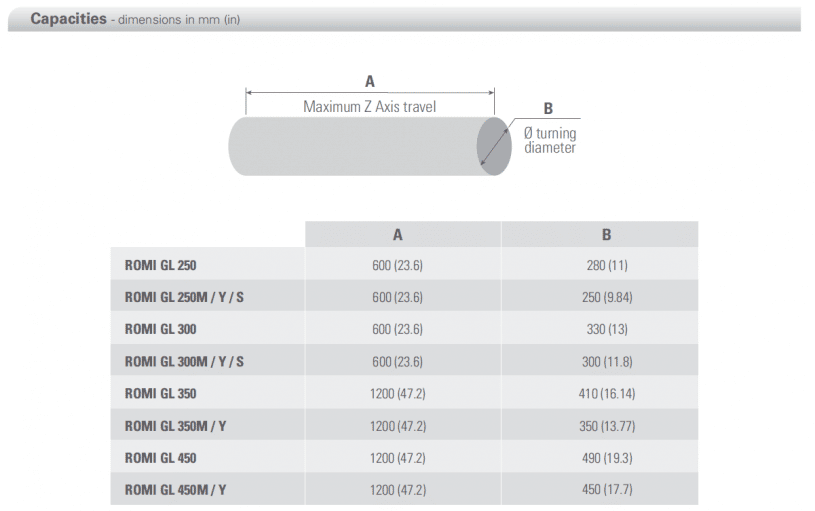

| Maximum cutting diameter | mm | T = 282 M, Y, S = 250 | T = 330 M, Y, S = 300 | T = 410 M e Y = 350 | T = 490 M e Y = 450 |

| Speed range (Headstock) | rpm | 6 a 6000 / 4 a 4500 | 4 a 4500 / 3 a 3500 | 3 a 3000 / 2 a 2500 | 3 a 3000 / 2 a 2500 |

| Spindle nose | ASA | A2-5'' / A2-6'' | A2-6'' / A2-8'' | A2-8'' / A2-11'' | A2-8'' / A2-11'' |

| Rapid traverse - X axis | m/min | 30 | 30 | 30 | 30 |

| Rapid traverse - Z axis | m/min | 30 | 30 | 30 | 30 |

| Number of tools / stations | un | 12 | 12 | 12 | 12 |

| AC Main motor | cv / kW | 19,4 / 14,3 | 25,2 / 18,5 | 34 / 25 | 40,8 / 30 |

Catalogues

Videos

Consult an expert

Do you need more information about this product? Find here the nearest specialist or send a message.