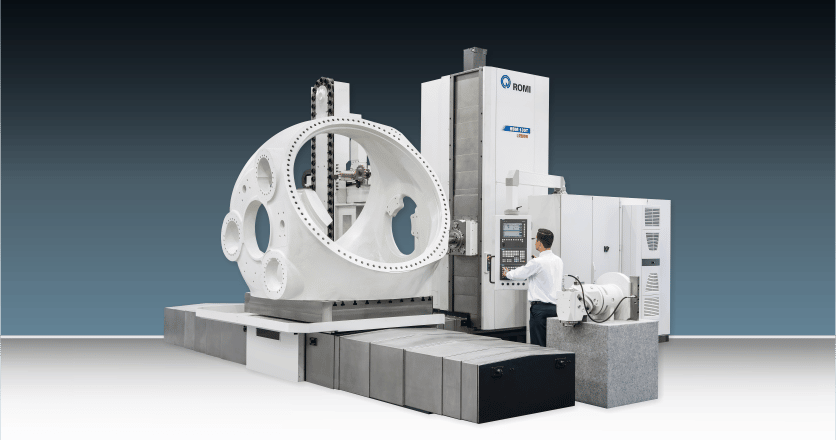

ROMI Lazzati HBM 130T

CNC Boring

Presentation

The boring machine ROMI Lazzati HBM 130T, equipped with CNC SIMENS, shows high capacity for chip removal, flexibility, accuracy and productivity on milling, drilling and tapping of large size parts, such as those employed in sectors of: oil & gas, ethanol, naval, energy power generation and other from base industry.

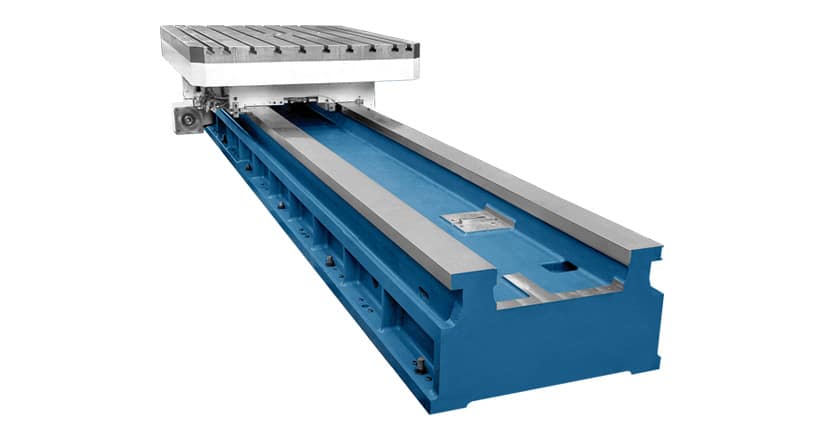

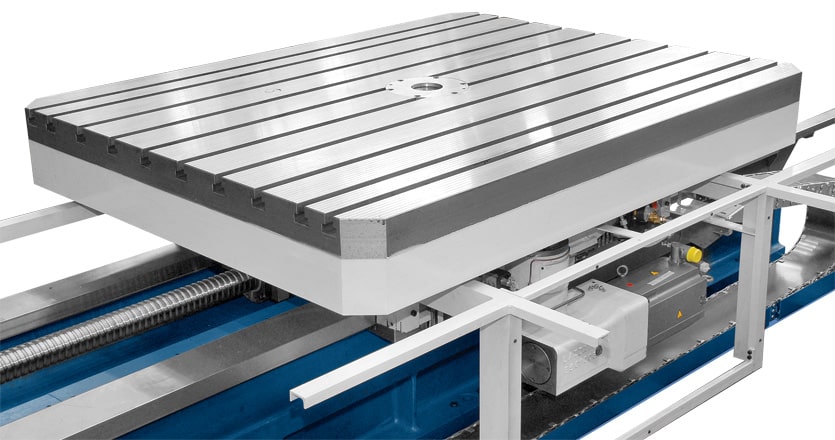

Equipped with Rotary table NC (axis b), it allows parts positioning in any angle, allowing for machining complex and interpolated parts. It can support parts of up to 12,000 kg and high machining loads, with excellent stability of the set.

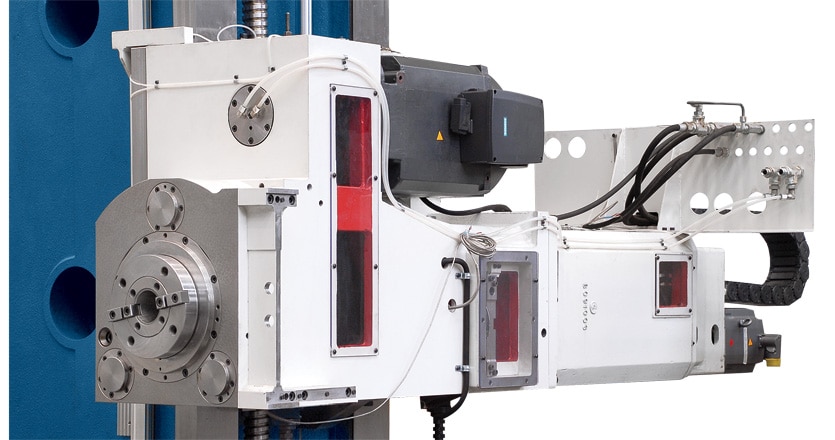

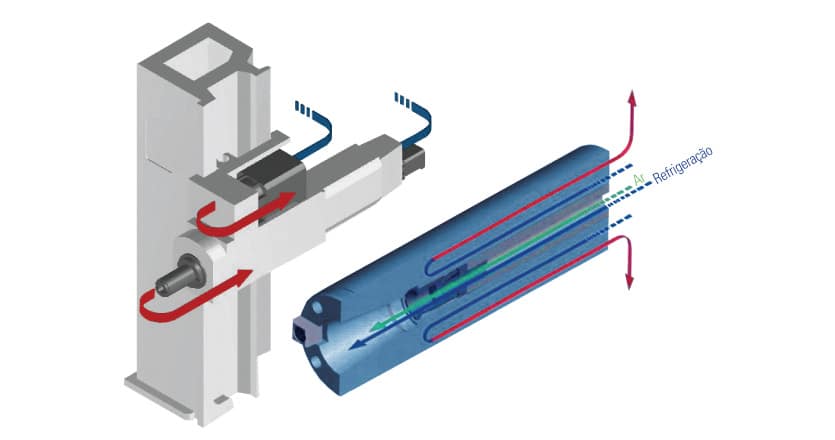

In order to keep heat stability and machining accuracy, the machine is equipped with thermo-stabilizer system, which spreads the heat generated by the bearing housings of the spindle.

Main technical features

| ROMI Lazzati HBM 130T | ||

|---|---|---|

| Ø Live Boring Spindle | mm (in) | 130 |

| Spindle taper | ISO | 50 |

| Max. Rotation Speed | rpm | 5 a 3.000 |

| Headstock Vertical Travel (Y axis) | mm (in) | 2.000 or 2.500 |

| Table travel (X axis) | mm (in) | 4.000 |

| Longitudinal Column travel (Z axis) | mm (in) | 1.800 |

| Live Boring Spindle Travel (W axis) | mm (in) | 800 |

| Rotary NC Table Surface | mm (in) | 1.500 x 2.000 |

| Max. weight allowed (uniformly distributed) | kg (lbs) | 12.000 (26.500) |

| Tool capacity | un | 60 |

| Main motor (reg. S2 - 30 min) | hp / kw | 79 / 58 |

Videos

Consult an expert

Do you need more information about this product? Find here the nearest specialist or send a message.